Technical Data

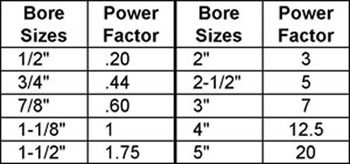

1) POWER FACTORS: Developed Force in Pounds Equals Power Factor times Air Pressure (P.S.I)

1) POWER FACTORS: Developed Force in Pounds Equals Power Factor times Air Pressure (P.S.I)

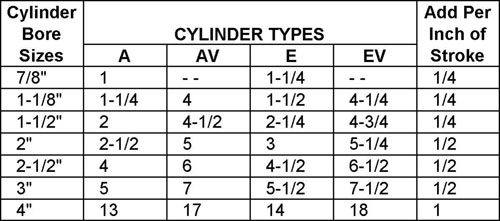

2) WEIGHTS:

2) WEIGHTS:

-

- Cyl-Check: 5 Ibs. plus 1/2 Ib. per inch of stroke.

Valves:

-

- 2 & 3-way: 3/4 Ib.

- 4-way: 1/4” thru 1/2” N.P.T. 3-1/4 Ibs.

3) LUBRICATION: All Allenair Cylinders are pre-lubricated, at time of assembly, with a specially formulated long lasting lubricant. Any additional lubrication should be used sparingly so as not to over-lubricate the Cylinder and wash out the pre-lubrication. A petroleum based lubricant of 100 to 200 SSU viscosity at 100° F (37.78°C) and an aniline point of 200°F (93.33°C) or greater can be used as a lubricant.

DO NOT USE LUBRICANTS CONTAINING ADHESIVES, SOLVENTS, DETERGENTS, GRAPHITE, PHOSPHATE ESTERS, FIRE RETARDANTS OR SYNTHETIC OILS.

4) SEALS: Standard seals used in Allenair equipment are Nitrile (BUNA-N) Compound. Buna-N has an operating temperature range of – 40°F to +250°F maximum. A fluorocarbon compound (Viton) having an operating temperature range of +10°F to +350°F is available.

Special seal compounds are also available.

5) STROKE TOLERANCE: Normal stroke tolerance is ±1/32”. On Back-to-Back, 3-Position, and Tandem Types, total stroke tolerance is ±1/16”. Closer tolerances are available at additional cost.

6) WATER SERVICE: The materials used in Allenair Cylinders are corrosion resistant. (Brass or Stainless Tubes, Stainless Steel Rods, Aluminum Heads and Piston.) Under the severe demands of water service, however, we recommend Double Rod Packing and hard coating the aluminum parts. These options are available at additional cost.

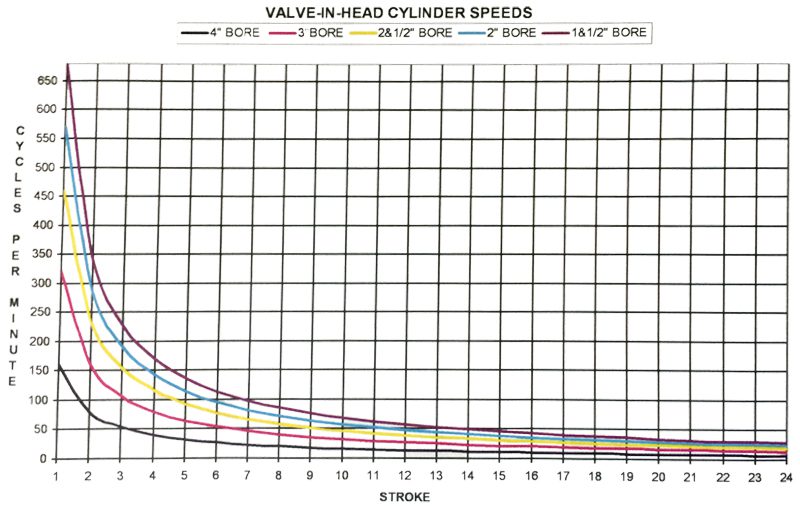

7) VALVE-IN-HEAD CYLINDER SPEEDS: These figures are based on a no load Condition operating at 100 P.S.I using an Allenair Cylinder Model VCR.

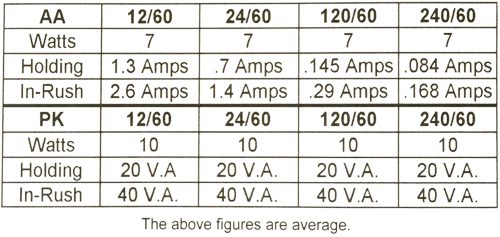

8) COILS:

- Solenoid operated units require a minimum Electrical contact of

25 milliseconds. - Our Solenoid Valves will build up to 80% of line pressure at the Cylinder ports within .037 seconds From the time of electrical contact.